Dye sublimation is a popular printing technique used to apply intricate designs, vibrant colors, and sharp text onto tablecloths, among other fabrics and materials. This process is particularly favored for creating high-quality, durable tablecloths suitable for events, trade shows, and promotional use. Here’s a breakdown of how dye sublimation works, particularly in the context of printing on a tablecloth:

What Is Dye Sublimation?

Dye sublimation is a digital printing technology that uses heat to transfer dye onto materials such as fabric, plastic, card, paper, or ceramics. Unlike traditional printing methods that lay ink on the surface of a product, dye sublimation involves turning solid dye into a gas without passing through a liquid form (sublimation) and bonding it directly with the fabric fibers.

The Process of Dye Sublimation for Tablecloths

- Design Creation: The process starts with creating a digital design. This design can include anything from logos and graphics to photographs and text. The complexity and vibrancy of the design are not limited by this technique, which allows for a wide range of creative possibilities.

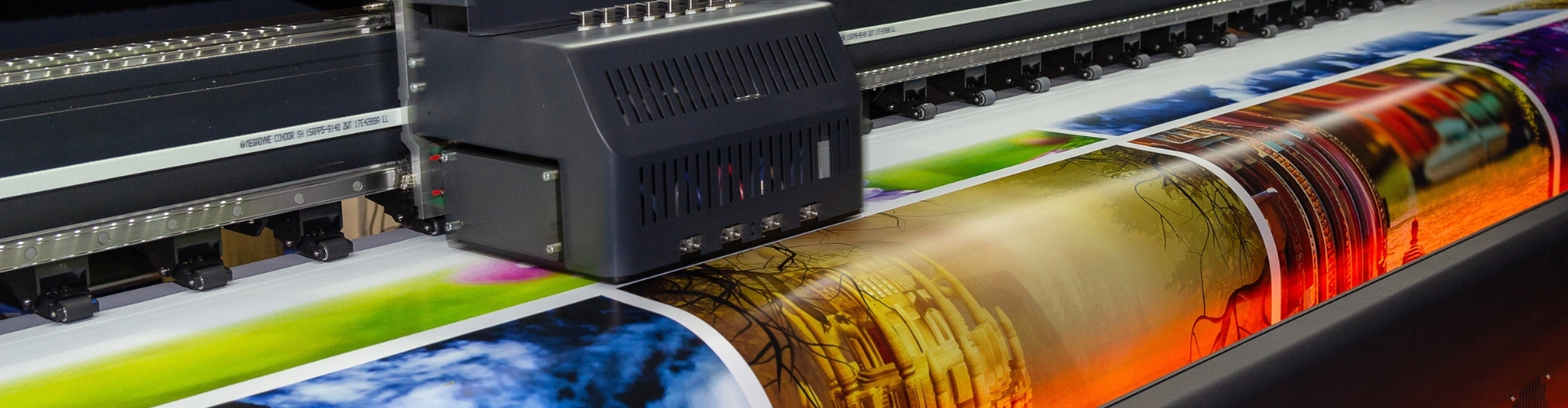

- Printing the Design: The next step involves printing the design onto a special type of paper known as sublimation paper using sublimation inks. These inks are unique because they can turn from a solid directly into a gas under heat and pressure.

- Transferring the Design: The printed paper is then placed on the tablecloth fabric, and both are subjected to high temperatures and pressure using a heat press. The heat causes the sublimation inks to convert into a gas, and under pressure, the dye molecules embed themselves into the fibers of the fabric.

- Permanently Infused Color: As the fabric cools, the dye molecules return to their solid state, becoming a part of the fabric. This results in a print that is exceptionally durable and resistant to fading. The colors are vibrant, and the resolution of the print is high because the dye bonds at a molecular level.

Advantages of Dye Sublimation for Tablecloths

- Durability: The dye becomes part of the fabric, making it resistant to fading and washing out. This is particularly advantageous for tablecloths used in high-traffic environments or those that need frequent cleaning.

- Quality and Versatility: Dye sublimation allows for complex and colorful designs that are as durable as they are attractive. The technique can be used on various synthetic materials like polyester, which is a common fabric for tablecloths.

- Touch and Feel: The process does not affect the feel of the fabric; the tablecloth remains as soft and pliable as it was prior to printing. This is a significant advantage over other methods that can leave a stiff, plastic-like feel on the fabric.

- Eco-Friendly: It is considered more environmentally friendly compared to other methods. The dye sublimation process produces minimal waste and uses less water and energy.

Dye sublimation is an excellent choice for producing high-quality, vibrant, and durable printed tablecloths that can stand the test of time. Whether it’s for a corporate event, a vendor at a market, or a special occasion, sublimated tablecloths offer a professional look with the practical benefits of longevity and maintenance ease.